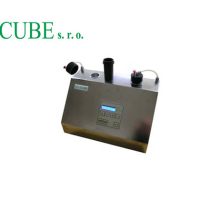

CO2 Analogue Measuring Instrument-GMD, GMDK

Description

Measuring device makes it possible to determine the CO2 content in cylindro-conical fermenters, fermenting tanks, or KEG casks and it is either in volume percentage or in grams/litre. The device for determination of CO2 content is based on the Henry law principle. The CO2 content is determined with the help of measurement of balanced value of temperature and pressure after the mechanical fluttering of CO2 dissolved in beer. Preceding the measurement the operator puts the button to flutter the CO2 in a low position and connects the device with the help of the rubber hose to cylindro-conical fermenter tank or to the fermenting or to the supplied adapted head attached to the KEG cask. This head makes it possible to attain the necessary overpressure in a KEG cask thus securing the samples withdrawal. The operator with the help of the closing valves fills a the vessel with the beer sample. Fluttering is done by using two times the piston pump placed on the top of the device. You switch on the device by depressing the “ON” button on the membrane keyboard. The value of the CO2 content can be watched on a display after depression of the “enter” button in CO2 menu. The device cleaning after the measurement is easy and fast. It consists of a connection to the water pressure distribution with open ball valves and water is circulated with the repeated depression of a button that is placed on the top of device during water circulation. The operator holds the the device in a vertical position during the circulation of water so that the whole vessel can be filled by water. We disconnect the device of water pressure distribution after cleaning. One removes the rest of rinsed water by turning the device upside down. During the whole time of handling the device (during measurement and cleaning) the operator has the device hung by sling on his neck which makes it possible for the operator to have both hand free during measurement. Everyone who works in such working conditions will appreciate it.

| Technical parameters: |

|

| Accessories: | Withdrawal head for KEG, pump – it is not part of the supply – only on customer’s demand. |

| Multipurpose uses of device: | The device is equipped by a microcomputer that makes it possible to perfect comfort and also benefits the staff by its versatility. The device makes it possible to separate the measurement of beer temperature and pressure in cylindro-conical fermenters, fermenting tanks or KEG casks, and CO2 content measurement. It is supplied in two versions:

|

| Range of suply: | The measuring device, little hoses for withdrawals (two pieces), user’s guide. |

| Files: | Measuring device digital – GMD for measurement of CO2 (CO2 GEHALTEMETER) |